ECE 2A:

Circuits, Devices, and Systems

Fall

2010

Tips on Soldering

Here is a

summary sheet in PDF form: How to solder

Other

on-line help: The

Basic Soldering and De-soldering Guide

(How to solder; types of irons; de-soldering; troubleshooting. by Alan

Winstanley)

Good soldering results depend on a few but important steps

to follow as outlined below:

|

1. |

Pre-heat the soldering iron for

approximately five minutes, tin the tip with solder and rub on a moistened

sponge until it appears bright and shiny. Always brush the soldering iron tip

on the moistened sponge prior to each use to remove burnt rosin and to ensure

proper heat transfer. |

||

|

2. |

Add component to PC board.

For through-hole components, bend leads to hold component in place, and trim

excess. For surface-mount components, use a drop of epoxy to hold the part in

place. |

|

|

|

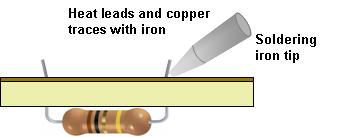

3. |

Place the pre-heated, tinned,

soldering iron tip, simultaneously, against the printed circuit board foil

and the component lead for approximately three to five seconds. |

|

|

|

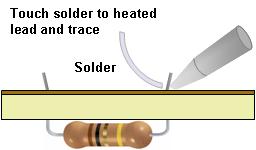

4. |

Apply solder to the component lead

opposite the soldering iron and permit the solder to melt and flow evenly

around the connection. Do not apply solder directly to the

soldering iron tip.. |

|

|

|

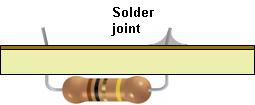

5. |

Next remove the solder and then

remove the soldering iron, and permit the joint to cool before attempting to

move the part or otherwise stressing the joint. When properly soldered the

joint should appear bright and uniform with an even meniscus. |

|

|

|

6. |

If you make a mistake, don't

worry! You can use solder braid (available in the ECE shop) to absorb

the solder from the joint and start over. Just apply the braid over the

joint, and press the hot iron against the braid and the solder. As the

solder melts, it will flow onto the copper braid. |

||